Search

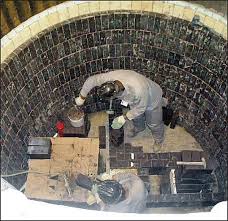

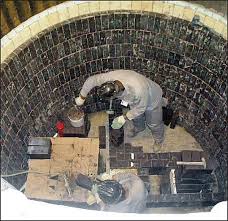

EAF Magnesia-carbon Bricks

|

On the basis of different application parts and conditions, using high-purity, high-density, large crystal magnesite and high-purity flake graphite as raw materials, adopting high-pressure shaping technique, and under the help of antioxidant, Horton supply series of magnesia-carbon bricks for EAF lining. The series of products have been widely used in steelworks worldwide. They show the features of high strength, excellent resistance against slag, good thermal shock resistance, high refractoriness etc., proving high performances.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||