Search

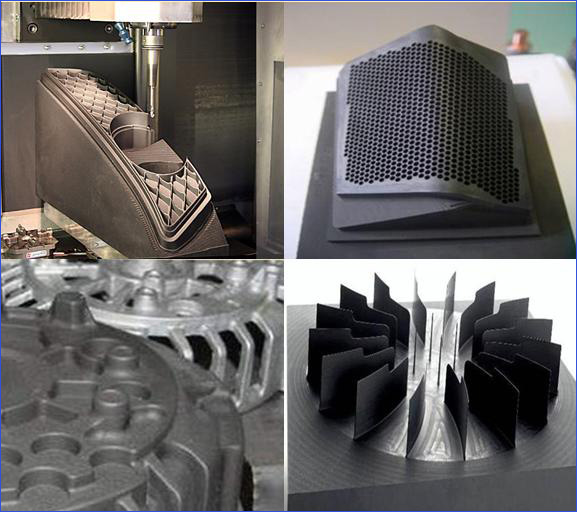

Graphite EDM Electrode

Advantages of Graphite EDM Electrode Compare to Traditional Cooper Electrode

Lighter weight: Density of the graphite is only 1/5 that of the copper, therefore the graphite is more suitable for the discharging of large electrode.

Faster process speed: Speed of the machinework is 2 -3 times that of the copper electrode without any burr appearing after the processing.

Less loss: Spark oil decomposed carbonization is covered and the compensation electrode is consumed.

Lower material cost: Graphite price is 50% that of the copper electrode of the same volume.

Difficult to deform: Compared to the copper electrode, the graphite has the melting point up to 3650℃ without any deformation under high temperature, which is more suitable for processing the bone position electrode.

High-precision: It has no burr after the machinework and easy to polish.

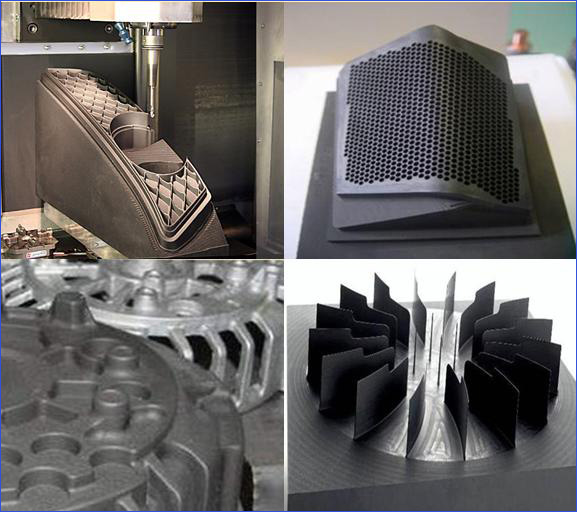

Advantages of Graphite EDM Electrode Compare to Traditional Cooper Electrode

Lighter weight: Density of the graphite is only 1/5 that of the copper, therefore the graphite is more suitable for the discharging of large electrode.

Faster process speed: Speed of the machinework is 2 -3 times that of the copper electrode without any burr appearing after the processing.

Less loss: Spark oil decomposed carbonization is covered and the compensation electrode is consumed.

Lower material cost: Graphite price is 50% that of the copper electrode of the same volume.

Difficult to deform: Compared to the copper electrode, the graphite has the melting point up to 3650℃ without any deformation under high temperature, which is more suitable for processing the bone position electrode.

High-precision: It has no burr after the machinework and easy to polish.