Search

Centrifugal Casting Alloy Indefinite Chill Cast Iron Roll and Ring |

|

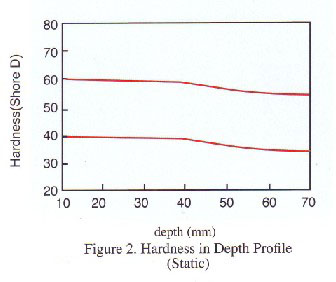

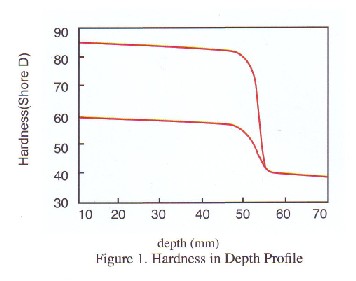

The shell has a remarkable mechanical performance. With virtually no fall of in hardness due to the quantity of graphite remains basically unchanged throughout the working layer. The hardness of roll depends mainly on the type of matrix, namely sorbite, bainite or martensite.

Applications For the finishing stands of continuous rolling mill of strip and bar, the pre-finishing stands of high speed wire, the intermediate and the front of finishing stands of small section, also utilized in thin plate and straightening roll. |

|||||||||||||||||||||||||||||||||||||||||||||||||