|

TiC-based Cemented Carbides

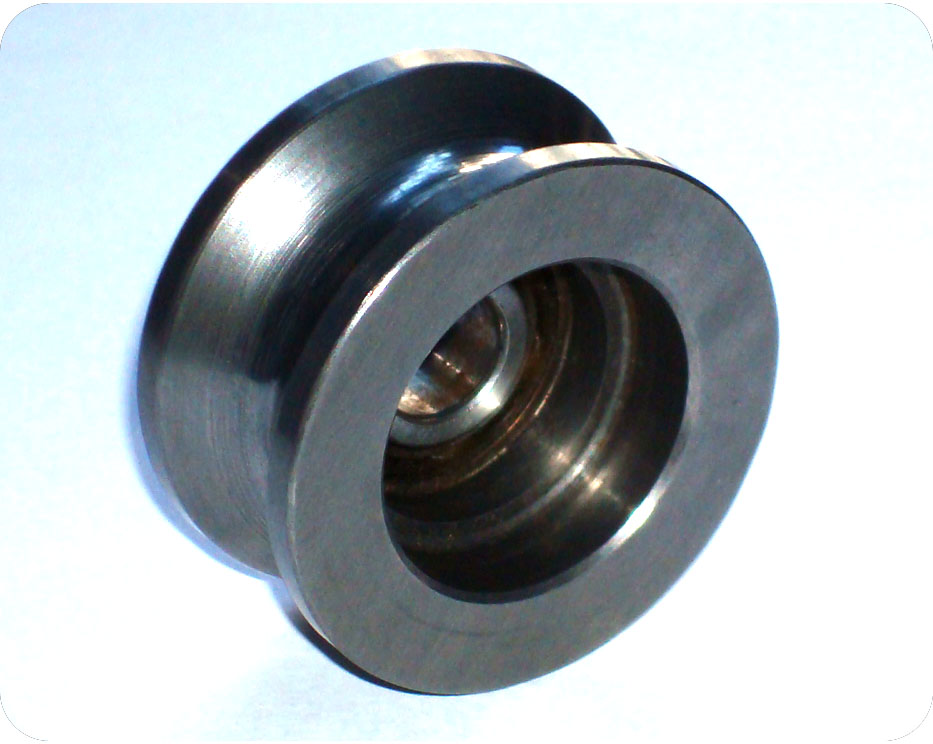

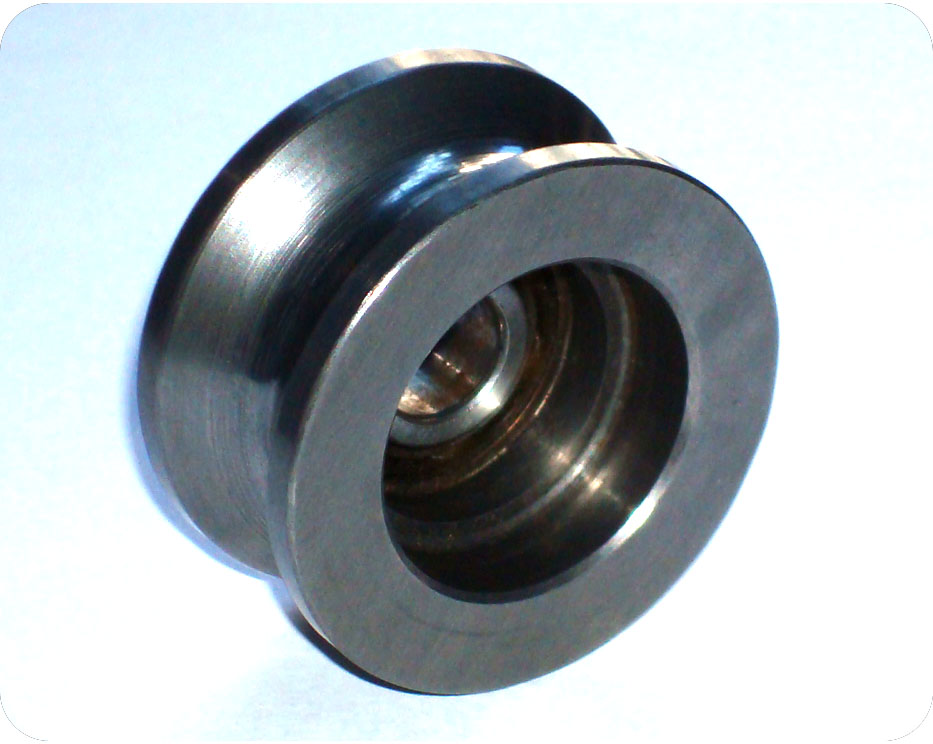

The guide roll made of TiC-based Cemented Carbides are the main consumptive parts, completed together with cemented carbide roll-rings in rod and wire milling in steel industry to ensure that the heated steel can be exactly guided into roll groove to prevent steel winding and tail swing.

TiC-based Cemented Carbides and their mechanical properties

|

Grade |

Main Components |

Density

g/cm3 |

HRA hardness (20。C) |

N/mm2

Transverse Rupture Strength

(20。C) |

KN/mm2

Young’s modulus |

Coefficient of thermal expansion 10-6 |

Applications |

|

HTN-1 |

(Ti,W)C - Ni |

6.40~6.70 |

≥84.5 |

≥1500 |

370 |

7.0 |

Guide roll |

|

HTN-2 |

(Ti,W)CN- Ni |

6.35~6.55 |

≥83.0 |

≥1600 |

360 |

7.0 |

Guide roll |

Features:

-

Excellent crack resistance.

-

Good self-lubrication ability and low friction factor

-

Good wear and corrosion resistance

-

Resistance to thermal impact better than that of alloy steel, with a life time 20~50 times that of the latter.

-

Non-magnetic, not easy to be adhered by metal.

-

Smaller specific gravity, good acceleration property, prolonging bearing performance life

|

|