Search

Tungsten Carbide Ring

|

|

|||

|

Application of tungsten carbide roll With high strength, high hardness and good wear rear resistance, tungsten carbide rolls (composed of WC, Co, Ni and other rare metals) are developed for high-speed wire rolling. To make the best used of carbide rolls, attention should be paid to things listed below:

Choose the appropriate grades for different stands according to the groove shape rolling speed.

Before installation, cheek the roll, tapered housing and roller. The match between roll, roller and tapered housing should not be tight or loose. The same grade is recommended for the same stand.

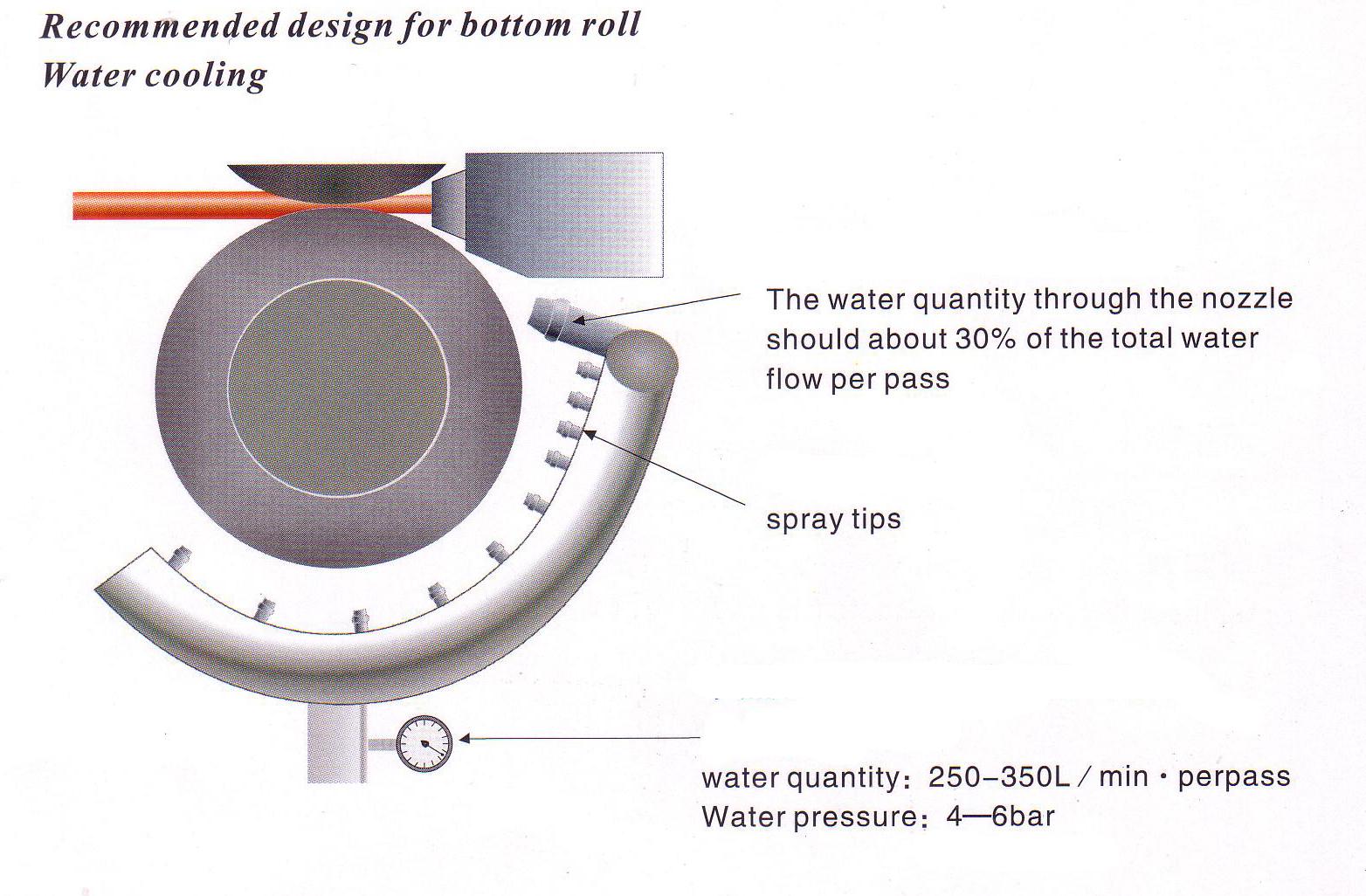

Rolls must be cooled down to prevent thermal fatigue crack and to prolong the service life. 4—6 bar cooling water pressure is recommended for finishing stands, and flow quantity of 250-300L/min, per pass is required. The water jet angle and the distribution of nozzles are shown as follows:

|

|