Search

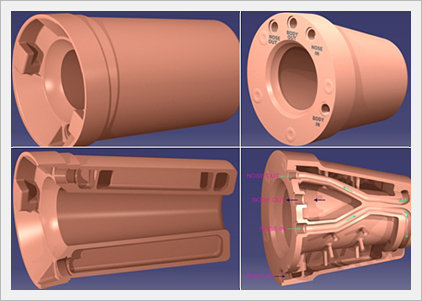

Blast Tuyere/Copper Tuyere

Blast Tuyere/Copper Tuyere

Tuyeres can be produced in different designs as single-chambered, double-chambered and assembled forged nose to the casted body. To make

the lifetime longer, advanced production technics are carried out.

Features:

1. Wide Scope for choose--- Single-cavity Tuyere, Double-cavity Tuyere, Three-cavity Tuyere, Baffled Tuyere, . etc

2. High purvity of Copper Content--- Made of Copper of CU≥ 99.5%, which increase the electric conductivity and assure the life-span of the Tuyere.

3. Approved Welding Technology--- Matured welding technology gurantee the high performance and quality of the Tuyere.

4. X-ray Test good quality.

5. Tailor-made to your requirements.

One year at operation with the following specification:

1. Hot-blast pressure: 4,1 atm

2. Hot-blast temperature: 1250 °C

3. Blast rate (for 22 tuyeres): 4900 m3/min.

4. Natural gas flow rate (for 1 tuyere): 2000 m3/h

5. Oxygen consumption (for 1 tuyere): 1800 m3/h

6. Cooling water pressure: 5-5,5 atm

7. Cooling water consumption (for 1 tuyere): 15-20 t/h

8. Cooling water temperature: up to 35°C